Monitoring and verification of the office building - Hagaporten 3

Challenge

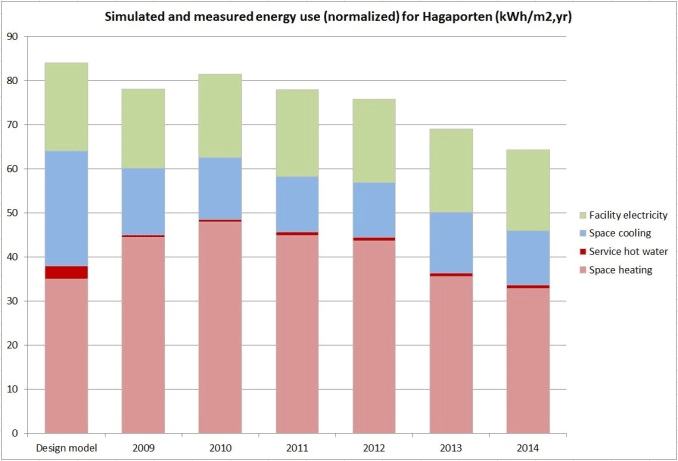

In 2006, a new outcome-based building code, using performance requirements on measured energy use, was introduced in Sweden. As a consequence, the interest in building simulation and monitoring and verification increased. The headquarters of the technical consulting company ÅF, Hagaporten 3, was designed and built in 2007/8. Hagaporten is almost 50,000 m2, including seven office floors and three garage floors. Skanska was the developer and later the building was sold to the real estate owner Norrporten. The requirement on measured energy performance was tightened up as Hagaporten was certified according to EU Green Building codes. The EU Green Building requirement is based on the national code and has in this case varied from 85 to 82 kWh/m2 per year.

Solution

During the design of Hagaporten, an IDA ICE simulation model was used to verify that the energy use was lower than the EU Green Building requirements. The simulation model was also used as a reference during the measurement and verification period. To support the measurement and verification activities, high-resolution trending of all HVAC (Heating, Cooling and Ventilation) signals started as soon as the EMCS (Energy Management Control System) was up and running. The performance of the HVAC systems were analysed as soon as data was available. Energy reports with prediction of full year energy use based on short term data was produced on a regular basis. A group with people representing the developer, the building and control contractor, the operators, the commissioning consultant and an energy specialist were formed to support analysis, decision and implementation of tuning actions in the control system.

Result

Initially the weather-normalized energy use was around 100 kWh/m2 per year but after initial tuning it was decreased to less than 80 also leading to a better thermal comfort. The trend-data based optimisation work has continued and the energy use was less than 70 kWh/m2 per year for the years 2013 and 2014 (see figure). The lessons learnt in this project have been transferred to several other projects. The energy modeling skills have been improved for several individuals involved in the project.

Print

Email

English

English  Svenska

Svenska  Deutsch

Deutsch  Suomi

Suomi  中文(简体)

中文(简体)