Evaporative cooling of a building envelope

Project facts

Type: Industrial, Detailed studies

Consultant: EQUA

Client: University of Stuttgart

Summary: Evaporative cooling study of a factory envelope. A tailor-made extension for IDA ICE was developed and used. Comparison between measurement and simulation showed very good agreement.

Challenge

The work was carried out in the context of the German research project ETA-Fabrik (ETA - Energy Efficiency, Technology, Application Center).

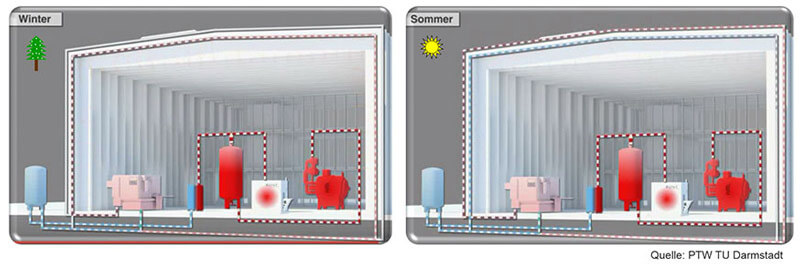

Its aim is the construction of a model factory with greatly enhanced efficiency through a combined planning of the subsystems ‘building’, ‘technical infrastructure’ and ‘machinery’. The project team included 36 partners from industry and research. In the factory, exhaust heat from the machines is transferred via a water flow to capillary pipes that are located in the building envelope. The envelope is then adiabatically cooled during the day by spraying it with rainwater. Overnight the envelope is cooled through longwave radiation.

The principle behind the envelope of the ETA Fabrik

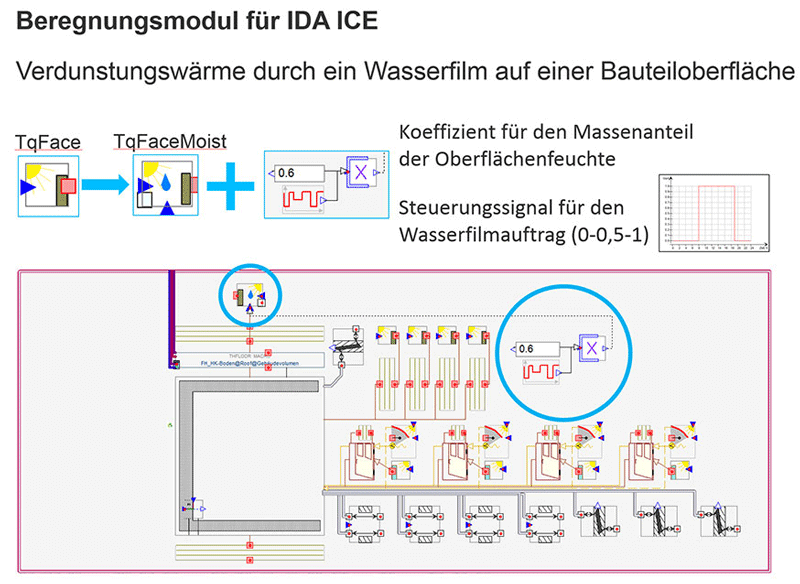

IDA ICE, the building simulation tool chosen to support the project, could however not model the adiabatic cooling process out-of-the-box.

Solution

The project partner University of Stuttgart, Institute of Construction Materials approached EQUA to develop a solution for the problem. The initial approach was to use the IDA ICE extension Ice Rinks and Pools, since it considers evaporative processes. It initially showed promising results but had the limitation that the evaporation could not be controlled (the building envelope of the ETA Fabrik is not continuously humidified, but the humidification is turned off when not needed to save water). EQUA therefore developed an extension that could model a non-continues humidification of an external building surface and quantifies the energy flows associated with the evaporation of the water and the cooling potential this generates. This extension was then incorporated into an IDA ICE model and the simulation-based performance predictions compared to measurements from a test rig.

Result

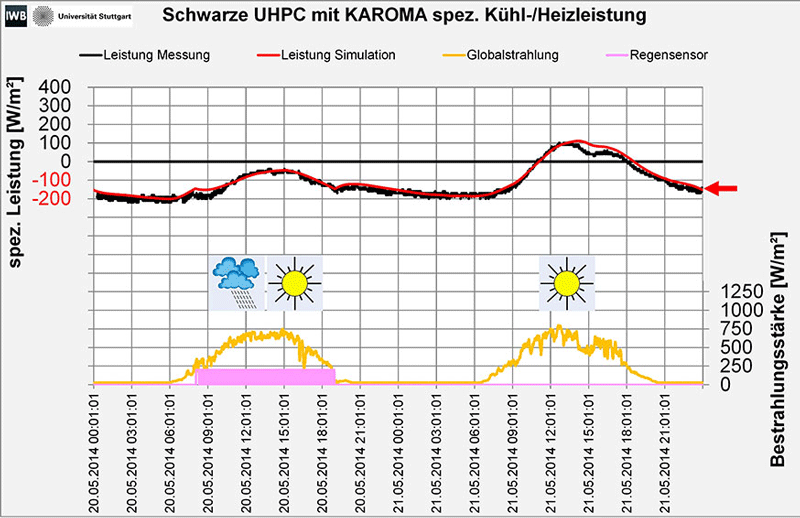

The comparison between measurement and simulation showed a very good agreement. This validation was important since the implementation contained certain simplifications. For instance is in reality the humidification modulated in intervals of several minutes whereas the evaporation in the model was assumed to be continuously.

Measured and simulated performance with and without humidification

With the good agreement it was concluded that the implementation was sufficiently accurate to interrogate different design scenarios, for instance the simulation of the entire ETA-Fabrik building or the evaluation of the impact of different supply temperatures for the envelope humidification.

English

English  Svenska

Svenska  Deutsch

Deutsch  Suomi

Suomi  中文(简体)

中文(简体)