Exhaust air heat pump for residential

Project facts

Type: Residential, Detailed studies

Consultant: EQUA

Summary: Creating an advanced plant models in order to size an exhaust air heat pump in a residential building, which is connected to a district heating system.

Challenge

In IDA ICE we have the possibility to create more advanced plant models by using ESBO Plant. By using ESBO plant it is possible to automatically create plants that for example use the exhaust air as a source for a heat pump. This can be useful when you need a rough estimation of the savings that can be achieved. However, a plant made in this way does not cover all aspects of a real plant design and will not simulate the true behavior of a real system layout. Luckily this is not a big problem. When using IDA ICE it is possible to create a plant model that looks like and simulates the real behavior by using the component models of the ESBO plant. In this particular case an exhaust air heat pump that works together with a district heating system was to be created.

The schematic of the system to be designed

Solution

The model of an exhaust air heat pump consist of two main parts, the plant and the air handling unit with the exhaust air cooling coil. A normal plant in IDA ICE is unlimited, but when using a detailed plant, all the valves, heat exchanges, heat pump etc. must be properly sized. The sizing data to be put into the model can be reached by clicking the buttons in the top right corner of the model.

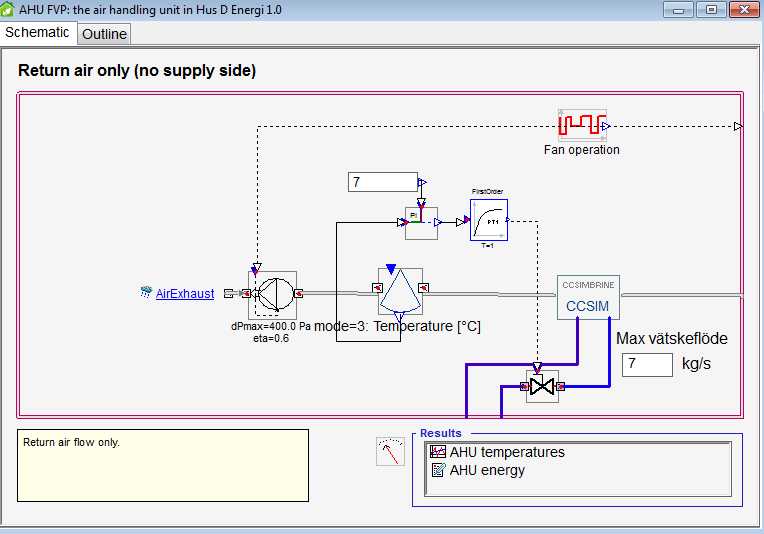

The air handling unit consists of an exhaust fan and a cooling coil. The coil is connected to the plant by using the built in connection between the plant and the cooling coil. A project can consist of multiple air handling units connected.

The Air handling unit connected to the Plant model

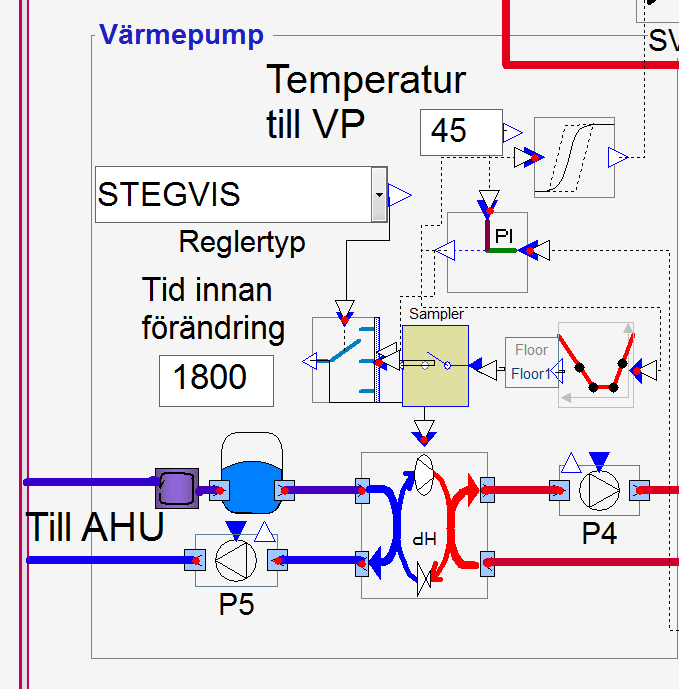

The heat pump is controlled to keep the return water temperature at a constant level. To simulate a heat pump with multiple compressors that gradually steps into action it is possible to set the type of control to stepwise. The minimum time for each step can be varied. This will make the simulation quite slow. The model will work better if it is possible to use continuous control.

A detailed view of the control of the heat pump. Here two different control algorithms can be selected stepwise or continuous.

Result

By using a more detailed simulation model the customer can test the influence of the sizing of the components on the energy usage. Most important is the sizing of the heat pump and the tank connected to it. Also, by using this plant the model gives a correct result of the used power for heating that is required to be within a certain limit according to the Swedish building code.

English

English  Svenska

Svenska  Deutsch

Deutsch  Suomi

Suomi  中文(简体)

中文(简体)